FuooTech Group | Manufacture of Vacuum Oil Purifiers

- Product Catagory

- Contact Us

- Tel:0086 23 8823 9845, Mobile: 0086-135-2739-0908,

- Fax:0086 23 8823 9845

- Contact:Mr. Kevin Dube

sales@fuoo.net

sales@fuoo.net sales@oil-filtration-engineering.com

sales@oil-filtration-engineering.com- Skype

kevinnchiang

kevinnchiang

- About us

-

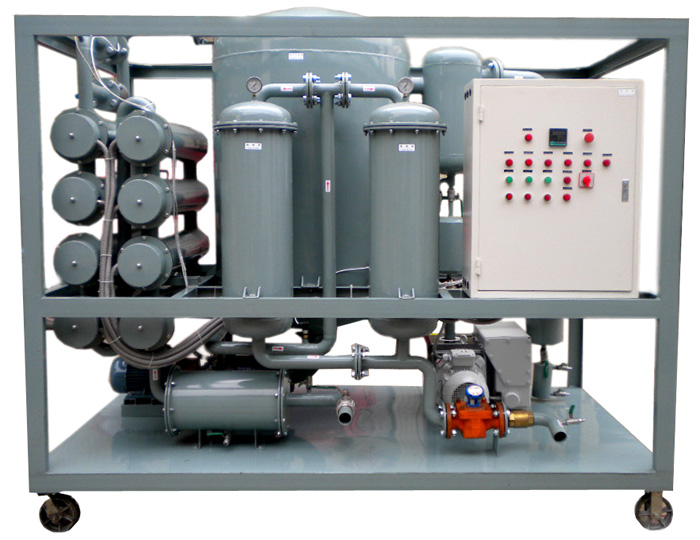

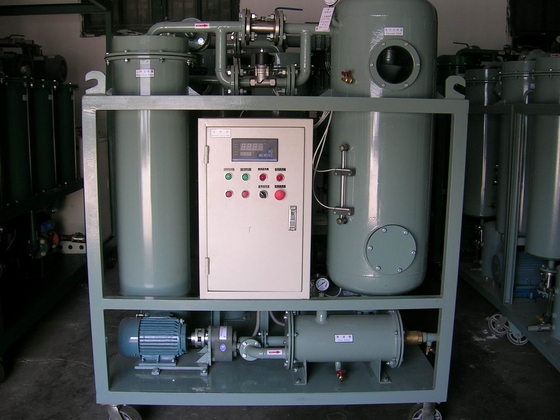

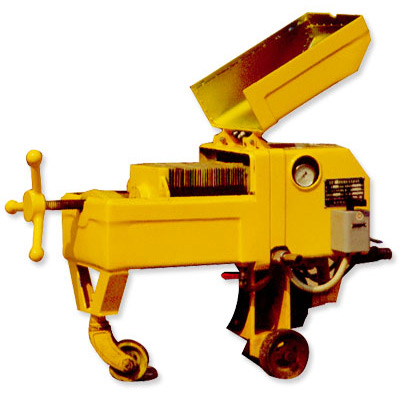

We are Specialized in manufacturing kinds of Oil Filtration Machines, transformer oil purification system, turbine oil filtration plant, industrial oil treatment device and engine oil recycling system, etc.

Our oil filtration equipment series are extensively used in the fields of electric power, petroleum, natural gas, mechanical manufacture, steel, metallurgy, railway, aviation etc. which consume lubrication oil.It's the principal products covering more than 100 kinds of products in 7 series and can meet different needs of customers. For special demands of cus... Read more

- Hot productsMore>>

- Address:No. 5 Hongshi Street, Jiulongpo District, Chongqing, China

- Tel:0086 23 8823 9845, Mobile: 0086-135-2739-0908, Fax:0086 23 8823 9845

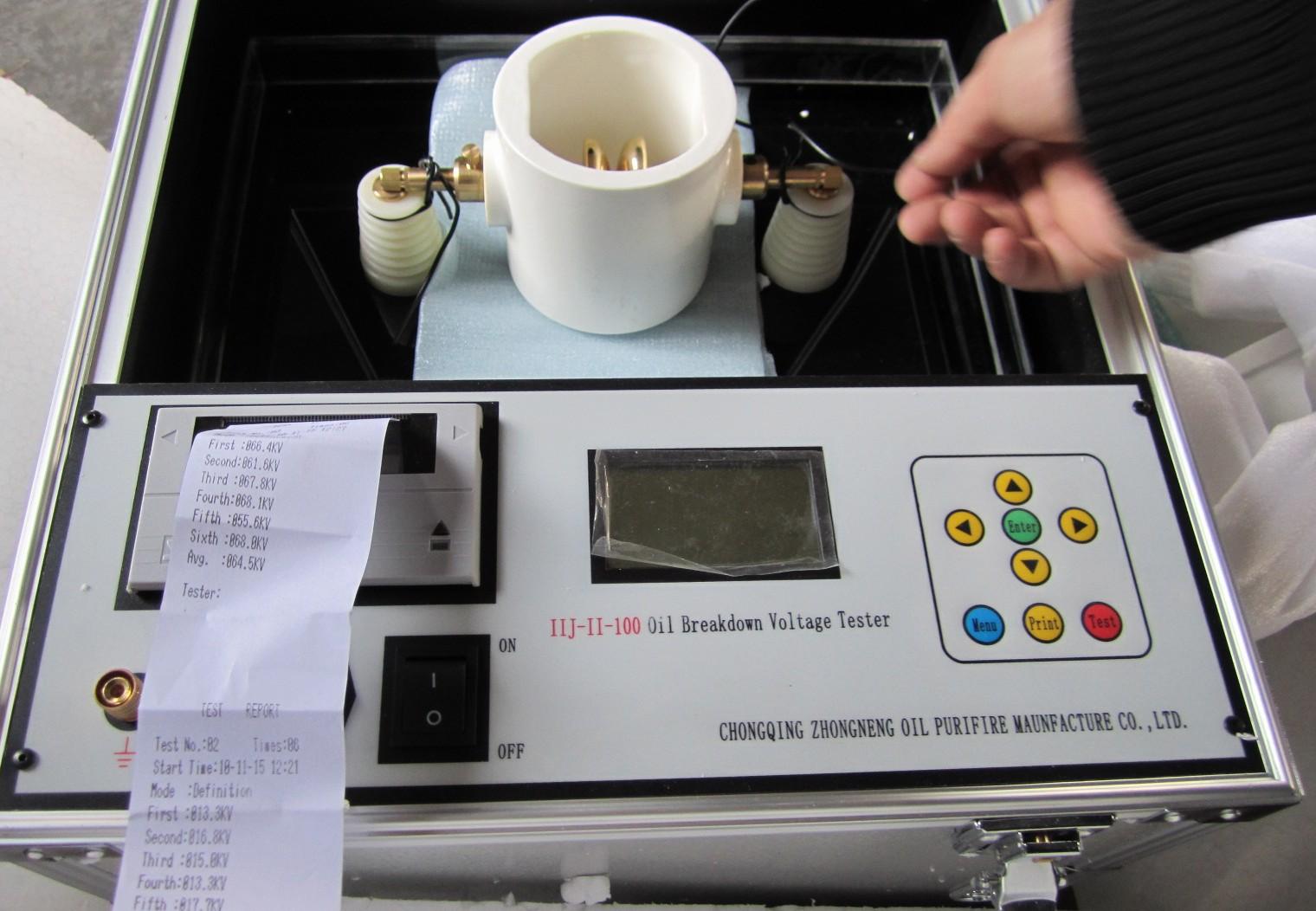

- Oil Filtration Engineering| Vacuum Oil Purifier| Transformer Oil Filtration System| Lube Oil Purifiers| Hydraulic Oil Filter Machine| Dielectric Oil Filtration Plant| Oil flushing equipment | Transformer Oil Tester & Dielectric Strength Tester | Transformer Oil Purification System | Vacuum Oil Treatment Plant